PRECITECH: Empowering Manufacturing Excellence

Pioneering networking events for quality manufacturing sectors, PRECITECH champions “Precision Meets Performance, ” This synergy yields outstanding results and accomplishments

- Seamless integration of accuracy and effectiveness

- Technology transfer opportunities

- Collaborative discussions and idea-sharing

- Resource conservation

Comprehensive Manufacturing Scope:

- Advanced Manufacturing

- Intelligent Manufacturing

- Smart Manufacturing

- Ancillary industries

- Emerging technologies shaping the future manufacturing landscape

India's Global Leadership, Rising Prominence:

The global community recognizes India for precision engineering and calibrated technology, achieving optimal results in valued production. driving optimal results in valued production.

India supplies crafted components to:

- Aero engineering

- Aerospace

- Defence

- Automobile

- Automotive

- Medical equipment

- Food processing

- Oil and gas

- Textile

- Infrastructure

PRECITECH empowers industry professionals to leverage precision and performance, fostering excellence, greatness in manufacturing.

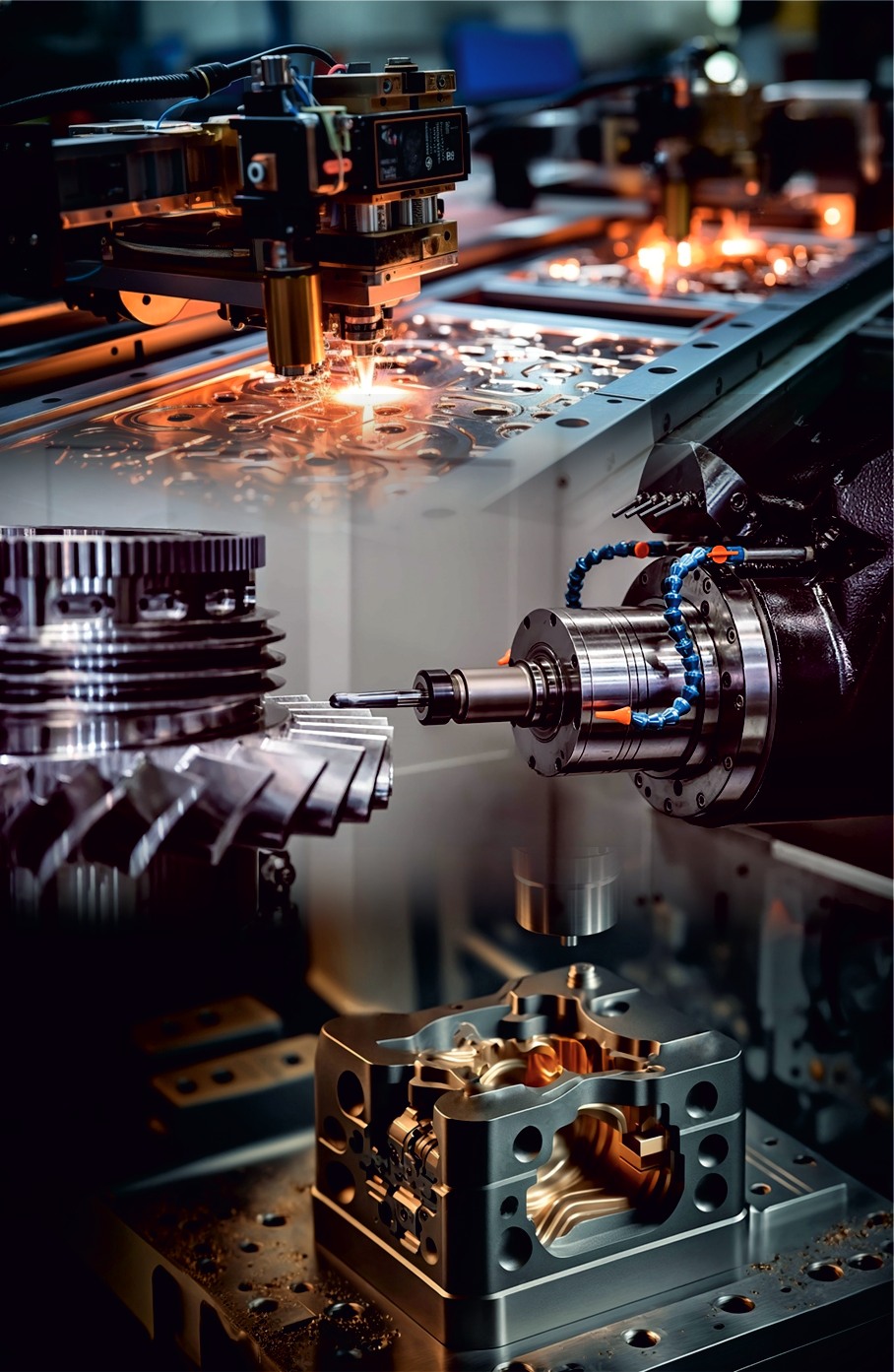

Metal Cutting

Cutting Tool, Insert, Tips, Diamond, Carbide-Tungsten Coated Special Purpose Cutting Tools & accessories, Holder, CNC-5 Axis, Machine and equipment, Wire Cut, EDM, Measuring, and Calibration equipment.

Metal Forming

A variety of processes and equipment, including laser marking, cutting, plasma cutting, welding, bending, power press and press brake, Punching machines, deburring, machines for product cleaning and finishing, coating equipment, and machinery for forging and die-casting.

Metrology

Covers a wide array of activities related to testing, measuring, inspection, gauges, including calibration, accuracy measurement, Coordinate Measuring Machine, mechatronics – mechanics, electrical, electronics, and computing to generate a simpler, more economical and reliable system. for measuring, and quality control.

3D & ADDITIVE MANUFACTURERS

Motion engineering, drive and control systems, welding and material handling, power transmission, and applications in the most mechanised manufacturing improve production controls in major Industry vertical.

PRODUCT FINISHING

A variety of processes, Ultra precision Grinding, Abrasive, Sand paper, Brush, Vibrating Screen, Metal treatment, Cleaning, Deburring, Drying, Polishing, Coating & Finishing.

CASTING AND FORGING, PRECISION INJECTION MOULDING (METAL)

A variety of processes and equipment, including Melting Casting, Cutting, machinery for forging and die-casting.

AUTOMATION & ROBOTICS

Reverse engineering, section includes CAD/CAM software, 3D scanning and printing technology, additive manufacturing, as well as technologies for manufacturing polymers, composite materials, metals, and lightweight materials. Appropriate for Development & research, before production line.

Fluid Power

Hydraulic, pneumatic systems, air compressors, and vacuum, generators. Oil and Lubrication helps in Improving Production capacities.

PLANT & ASSET MANAGEMENT

Research and development, training, logistics, and supply chain operations.

Maharashtra's and Pune's industrial landscape

Maharashtra: Contributes 13% of India’s industrial output= Business-friendly policies, robust infrastructure, and vast talent pool

Key manufacturing sectors: Aero Engineering, Aerospace, Automobile, Automotive, Construction Equipments, Defence, Infrastructures, Oil – Gas, Medical, Textile, IT and Education….

Pune:- Emerged as manufacturing hub and smart machinery centre =Driven by AI, quality production, time management, logistics =Auto cluster formation (Bhosari, Chakan, Pimpri-Chinchwad, Talegaon,) = Industrial growth extended to IT sector = Challenges: poverty, unique development trajectory =’Make In India’, support for emerging businesses

Key Players: DRDO=Dehu Road=Khadki Ordnance Factory =NIBE =SKF =Tata Advanced Technologies=Bharat Forge=Kalyani Forge =Viman Nagar =Walchandnagar Industries=Kirloskar =Cummins =Alfa Lavel = Premier =Thermax=Mahindra=Bajaj Auto =Force Motor =Tata Motors and many more….

In the 1950s and 1960s, Pune transformed from a quiet town into an entrepreneurial hub, welcoming industries that shaped its identity. The emergence of the ‘Auto cluster’ around Chinchwad, Talegaon, and Chakan marked the city’s industrial revolution, with companies like Bajaj Auto and Tata Motors leading the way. This growth spurred migration to Pimpri and Chinchwad, boosting real estate and prompting the formation of PCMC in 1982.

The 1960s to the early 2000s witnessed a trend of COEP engineers joining Pune industries. With the 1991 reforms, a shift toward research and development (R&D) occurred, driven by reduced red-tape and the need for innovation in the face of global competition. Indigenous R&D efforts became evident in product evolution, exemplified by Bajaj Chetak and Tata cars.

Pune’s industrial success didn’t stop there; it extended to the IT sector, further fueling the city’s growth. However, challenges like poverty persist, and while a robust manufacturing sector could address these issues, India’s unique development trajectory poses obstacles. Initiatives like ‘Make In India’ and support for emerging businesses are crucial for fostering a new revolution, empowering local manufacturing and contributing to India’s accelerated development.

Additionally, DRDO, Dehu road, Khadki Ordonance factory, BHARAT Forge, Kalyani Forging, and Walchandnagar Industries, NIBE, TATA Advance Technologies, Bajaj, Kirloskar, Mahindra have played pivotal roles in defence manufacturing, enhancing Pune’s industrial landscape. The giants in the automobile and automotive industry have not only attracted machining centres and ancillary units but also inspired machine makers to establish manufacturing setups, ensuring prompt delivery and immediate services in the thriving industrial ecosystem.

Aurangabad, Kolhapur, Mumbai, Navi Mumbai, Nashik, Nagpur, Thane, Uran is developed for various industry vertical

COMMUNICATION – KNOWLEDGE – DELIVER BUSINESS TECHNOLOGY:

At CKD BUSINESS TECHNOLOGY, we have introduced an innovative concept to invigorate the Exhibition Industry with renewed enthusiasm and vigour. While products from well-known brands inherently possess value, channelling that value to meet the customer’s specific desires requires meticulous planning. That’s where CKD BUSINESS TECHNOLOGY serves as a valuable intermediary, bridging the gap between the product and the end-user.

PRECITECH will host over 350 exhibitors, both from national and international backgrounds. Beyond being a highly successful industrial exhibition showcasing cutting-edge technology, it also serves as a powerful platform for achieving the communication objectives of participants. Positioned prominently in the minds of the audience, which is substantial and industry-specific, PRECITECH plays a pivotal role in facilitating connections and knowledge exchange.

FABRICATED STALL:

- 12,000 Per sq. mtr,

- 12 Mtr. (4m x 3m) with Standard Facility

- (Front Maxima, Carpet, Name Fascia, 1-Table, 1- Round Table, 3-Chairs, 1-Plug, Single Phase 5/15, 4-Spot Light)

BARE SPACE:

11,000 Per sq. mtr. Exhibitors need to construct design stall (Refer Exhibitors manual for guideline).

POSITION:

- 2 Side open (15 % Premium on Basic cost)

- 3 Side open (20 % Premium on Basic cost)

- 4 Side l-land (25 % Premium on Basic cost)

ADDITIONAL FACILITY:

available at extra cost: Please refer exhibitors Manual.

CKD BUSINESS TECHNOLOGY

2-1B, “SONARIKA”, 1st Floor, Chanda wadi,

C P Tank Road, MUMBAI 400 004.

TeL: +91 7738586871

email: sales@ckdindia.org

www.ckdindia.org

GST No.:27AMMPS0638N2ZC

PAN No.: AMMPS0638N

Enquire Now

OUR ESTEEMED EXHIBITORS

OUR VISITORS